Magnet wires is used to wind motos and transformers. No matter for rewinding or repairing, the conductors need to be splicing. Let’s get to know the three different basic joint method of winding wires.

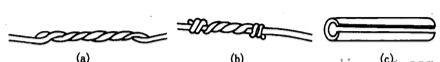

(1) When the diameter of round wires is less than 2mm, wires are usually to be twisted jointed first and then brazing. The wires should be twisted uniform, and two wires should mutually wind at least 10 circles. Both ends of the wires should be sealed, leaving no rag. Conductor’s twisted joint method is shown as (a) in the picture. After the twisted joint is completed, the brazing should be carried out then. When brazing, the tin liquid should fully penetrate into the gap at the hinge.

(2) When the diameter of round conductor is more than 2mm, it usually use casing first and then brazing. The casing is made by curved tinned sheet copper. Shown as Picture (c), it should leave a gap in the seam, so that it can be inject tin liquid. The inner diameter of the casing should be matched with the size of the wire, the length of the casing is generally taken as 8 times of the diameter of the conductor. Before connection, we should insert two ends of wires, which is removed insulation layer, to the casing, so that the ends of the two wire heads are butted to the middle of the casing and then braze. When brazing, the tin liquid should be fully injected into the casing from the side seam of the casing to fill the gap in the middle and the connection between the two ends of the casing and the wires, which cast the wires and the casing as a whole.

(3)When the sectional area of rectangular magnet wire is less than 25mm2,it also can be conneted by casing method, which is described above.

For more information, welcome to vistit our website: www.wirezoto.com or contect me-Joey Lin(Email address: sales02@wirezoto.com/ Whatsapp/skype/wechat: 0086-18857925196).