| 【Prev Products】 | 【Next Products】 |

|

|

|

|

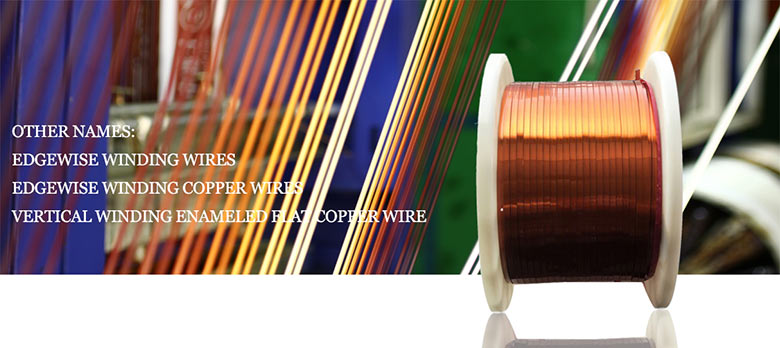

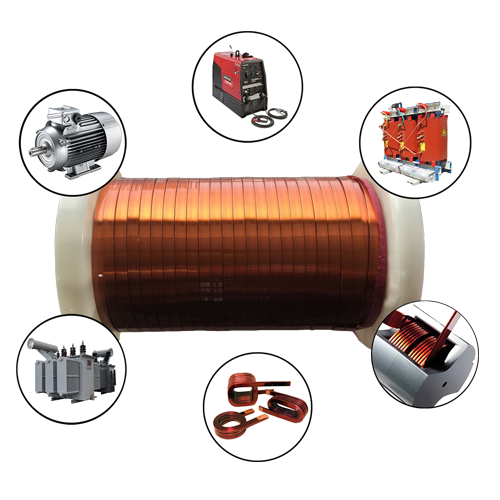

EDGEWISE ENAMELED COPPER WIRE

Production Process

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Package:Plastic spool, Wooden spool and according to customers requirements.

Test of Main technical

|

Standard |

IEC60317-29 |

||

|

Test Item |

Requirement |

Test Result |

|

|

Appearance |

Uniform color smooth surface |

Uniform color smooth surface |

|

|

Insulation Thickness |

0.06~0.11 |

OK |

|

|

Elongation |

≥30% |

40% |

|

|

Bending |

A side Bend 90° |

No film-cracking |

|

|

Adhesion |

Stretching 15% (≤1b) |

Qualified |

|

|

Heat shock |

220C / 240C 30min 3A |

No film-cracking |

|

|

Breakdown voltage |

≥2000V |

OK |

|

Send Inquiry

Send InquiryIf you have any enquiry about quotation or cooperation,please feel free to email us at Jennifer@wirezoto.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

Related Products

Related Products