Dielectric loss refers to the alternating electric field in the consumption of electricity in the insulating medium. For polymer solid dielectric materials, dielectric loss is usually used to study the relationship between its micro-molecular structure and macroscopic properties, from which to find the dielectric material with the best performance of the dielectric loss under certain conditions, in this way to explore the best process and control the purpose of polymer quality.

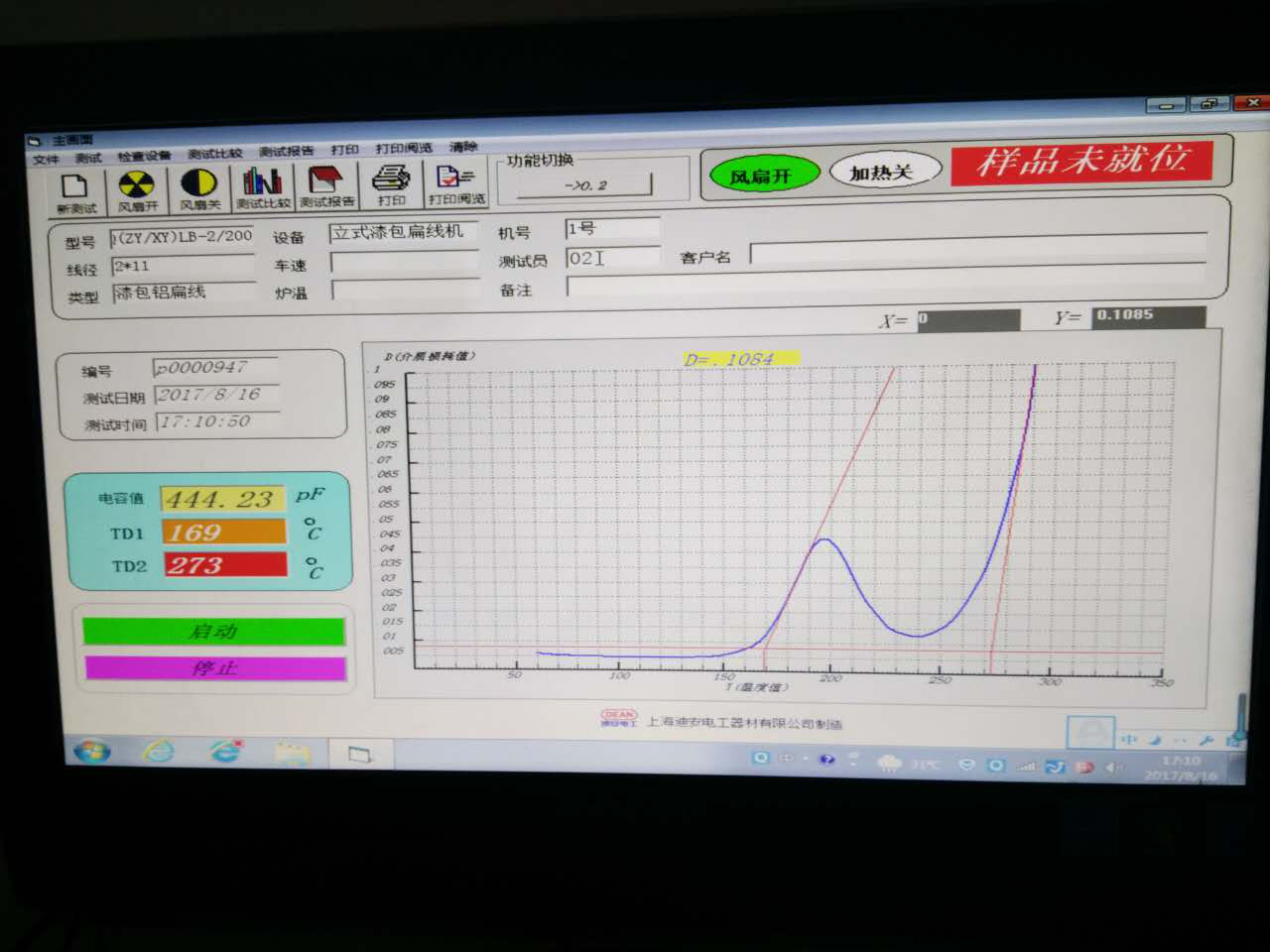

We can judge the degree of curing of enameled paint film from dielectric loss. We generally use tg-T curve to show dielectric loss.

Identify the stability of enameled wire performance

The use of dielectric loss testing can not only guide the painting process, but also identify the unstable enameled wire during storage quickly.

Enameled wire film curing degree of the pros and cons, not only related to the performance of the enameled wire during storage performance changes, the length of the life of the winding made, but also to test whether the paint process eventually adapt to the solvent evaporation characteristics of paint and paint Resin reaction characteristics. If the coating process does not eventually meet the two characteristics of the above-mentioned lacquer, although some of the properties of the enameled wire can be tested at the initial stage, this does not mean that the performance of the enameled wire remains constant during storage.