Enameled wire is a major type of winding wire, composed of conductor and Insulation. The bare wire after annealing and softening, and then painting, baking. But it can’t be easy to produce wire that meets both standard requirement and customers’ requirements. It is influenced by the quality of raw materials, process parameters, production equipment, environmental and other factors. Which cause the quality and characteristics of wire different. They both have mechanical properties, chemical properties, electrical properties, and heat properties.

As the rapid development of domestic and international motor manufacturing level, especially the the high ourput power abroad,as far as possible the small motor structure and production process of environmental protection, all of these present more strict technical requirements on the winding wire applied for all types of high-voltage motor stator parts; Winding wire applying to all type of high-voltage motor stator parts should have the performance of resistance to voltage, corona, high strength, high insulation and good flexibility; the existing enameled wire has not yet reached the requirements mentioned above.

This paper introduces a new type wire-155 class self-adhesive double fiber-glass mica tape wrapped copper flat wire.

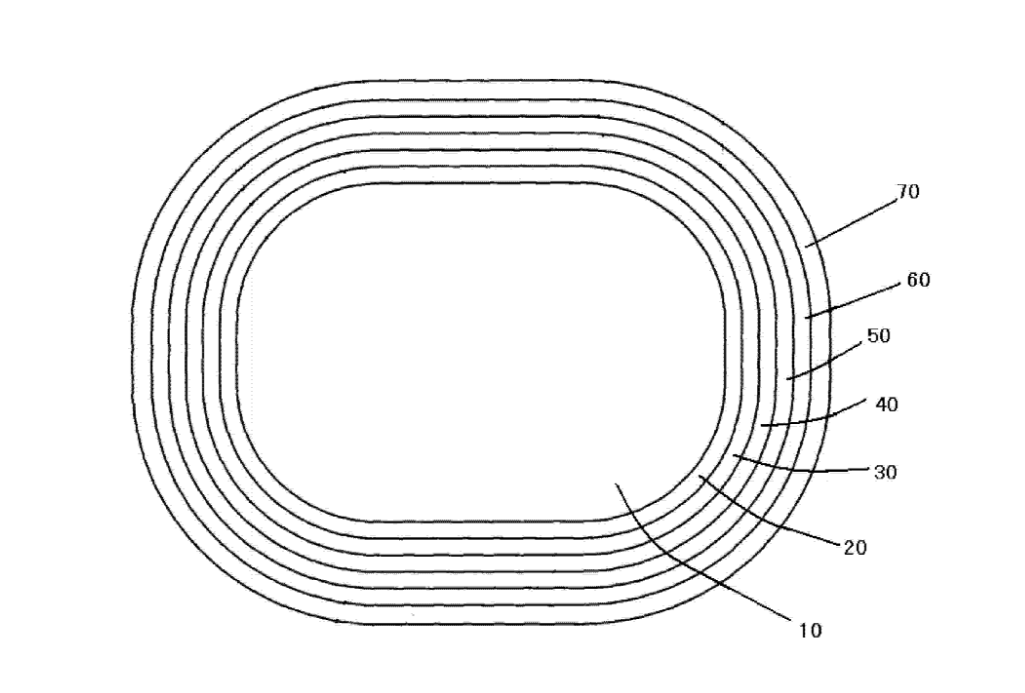

Shown as the picture, the number representing the corresponding parts, this 155 class self-adhesive double fiber-glass mica tape wrapped copper flat wire are composed of conductor and insulation. The conductor is flat copper wire(10), whose cross section is rectangular, and four corners of which are round corners; polyester film (20), mica tape (30), first polyester imide paint layer (40), double glass fiber (50), second polysterimide paint layer (60), and self-adhesive paint layer(70), which are wrapped on flat copper wire in turn. The height of the flat copper’s cross section is 1 to 5.6mm, and the length is 3.55 to 16mm. Insulation thickness is 0.5 to 0.9mm. The elongation of flat copper wire is ≥30%; the breakdown voltage is ≥4500V.

Advantages of this type wire

1、This wire is suitable for a variety of high-voltage motors with high performence on mechanical properties , resistance to corona, insulation, heat resistance and good technical characteristics.

2、This type of wire using polyester film to improve the resistance to voltage breakdown. The use of mica tape improves the corona resistance of copper flat wire; the use of double glass wire to improve the strenth of the wire, increase flexibility. Self-adhesive after heated can be helpful for stereotypes, widely used in high-voltage motor without skeleton.

Detailed Description

The size of the flat copper wire and radius of the four round corners should meet the national standard; at 20℃, unit length dc resistance R20 should meet the national standard GB7672.7.2.

The thickness of the new insulating layer can be 0.5mm、0.7mm、0.9mm, the deviation is -15%, and the self-adhesive property can be increased by 0.03mm. In the test, the wide and narrow sides winding on a certain diameter rod should not cracking to exposing the film’s surface.

When the height of flat copper wire is ≤2.5mm, its elongation is ≥30%; when the height of flat copper wire is >2.5mm, its elongaton is ≥32%;

When the insulation thickness is 0.5mm, the breakdown voltage is ≥4500V; when the insulation thickness is 0.7mm, its breakdown voltage is ≥6000V; when the insulation thickness is 0.9mm, its breakdown voltage is ≥6000V.