Paper covered wire is a type of winding wire which starts from oxygen-free copper rod or round aluminum rods extruded or drew by a certain size of the mold, and then wrapped by a specific insulating material. Zoto mainly offers Kraft Paper Covered Wire and Nomex Covered Wire at the current stage. Paper covered wire is mainly used for oil-immersed transformers, reactors and other electrical devices winding. Shanghai Zhongtuo Magnet Wires Co., Ltd. is specialized in producing paper covered wires and other winding wires. Our implementation of standards and quality requirements are listed as follows:

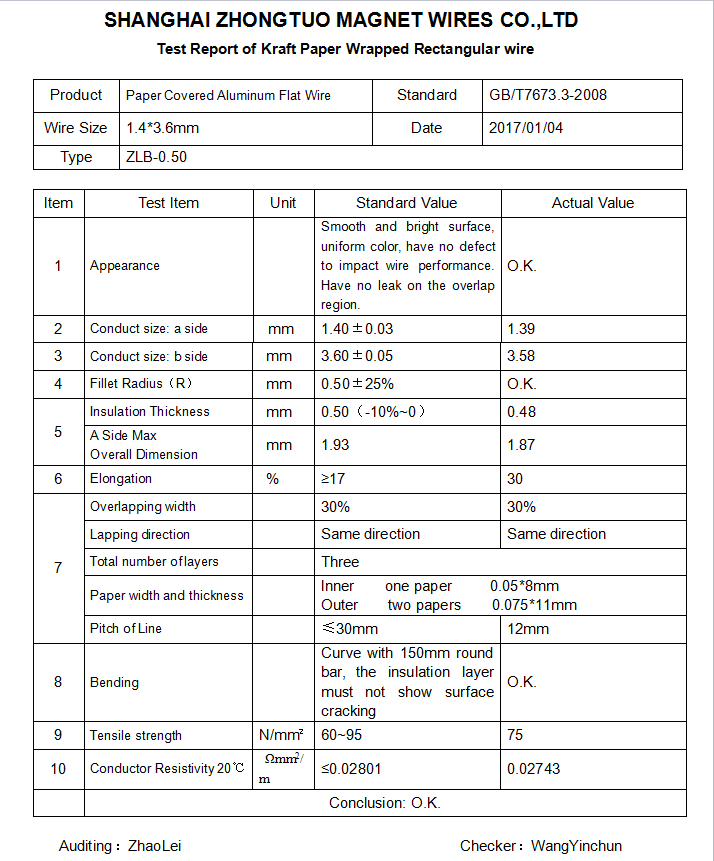

1. The implementation of standards: GB/T7673.3-2008 (Paper Covered Flat Aluminum Wire)

2. The quality requirements: the tape should be tight, uniform, smooth wrapped on the conductor. There should be no lack of layer, wrinkles, cracks, and gaps in tapes when overlapped. Thick insulation layer is allowed for Tape joints and insulation adjustment, but the length can not be greater than 500mm. (If any lack of layers, cracks happed in the production process, it will affect the insulation performance of the paper covered wires. And also resulting inwithstand voltage of the part and discharge, then breakdown and explosion will be followed for the transformer. However, if the overall size is too big due to thick insulation thickness. The overall coil size of the transformer will be too large, the outside shell is difficult to fit as well.

The test report for Kraft paper covered flat aluminum wire is showed as below for reference only:

Above is our concise introduction to the implementation of standard and quality requirements for paper covered wire. If any further questions or any interests in the winding wires, welcome to find us by email, we will be happy to be on service for you.