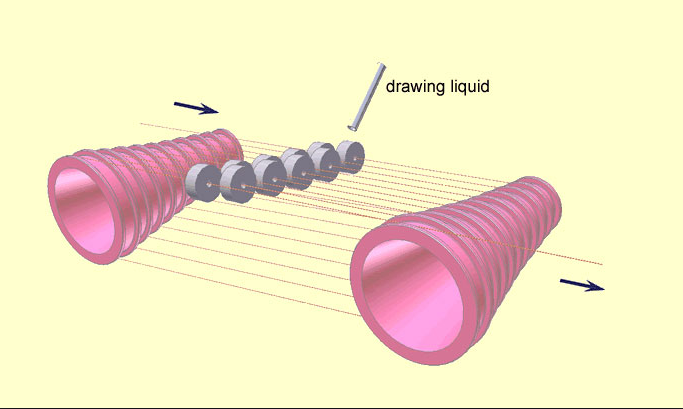

Generally there are two methods to paint enameled wires. One is by mold painting method in other words diepainting method and the other is by blanket painting method.

1. If coating with a mold making H class enameled rectangular wires, when the mold aperture with appropriate size, enameled wire paint layer thickness can be maintained for a long time stability, which is no like blanket method to adjust the thickness of layer too frequently .

2. Mold painting method can keep enameled wire surface uniform and smooth of round winding aluminum wires,without matt surface, bubbles, particles and other defects. When the furnace temperature, speed and stablequality of copper/ aluminum conductors, mold painting method has higher rate of graded product than othermethods.

3. When produced by Die painting method making polyvinyl acetal enamelled round copper wire, we can use the original paint which can increase the coating the solid content, and it can save the solvent, but also reduce the paint process.

4. The molds need to be cleaned after a period usage, but generally can maintain field days. Compared with the blankets in the use of the day after the replacement, Die painting method can reduce the waste and also save thepaints absorbed by the blankets.

5. The mold has the advantages of simple structure, low costs, a set of molds can be applied after seven or eight years or longer without damaged. But if by blankets way there are huge blankets consumption each year.