I, The thermal class of enameled wire

|

thermal class |

Y |

A |

E |

B |

F |

H |

C |

|

Max operating temp. |

90℃ |

105℃ |

120℃ |

130℃ |

155℃ |

180℃ |

﹥180℃ |

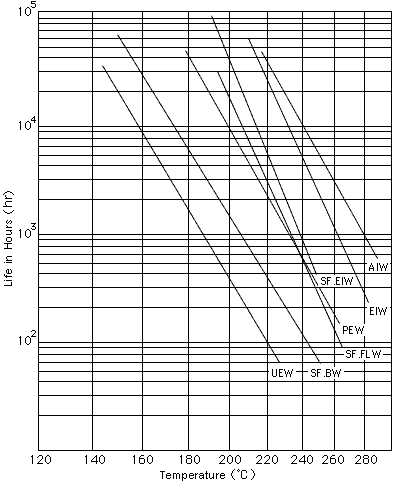

II, The chart of heat resistance life different type of enameled wires

III, Enameled Wire Use General Precautions:

1, Confirm the project before use,

Pay attention to the enameled wire models, specifications before the enameled wire putting into winding machine, to check if the wire meet the requirements to avoid abnormal phenomena.

2, Carefully handle the wires during carry

As the enameled wire film is very thin which is very vulnerable to be damaged by sharp objects. So the handling process must be very careful to prevent collisionto damage enameled wire.

3, Storage

First, to maintain the integrity of the enameled wire packaging to prevent damage caused by broken packaging to lead the enameled wire contamination. Usuallythe enameled wire should be stored away from dust, metal debris, moisture and sunlight.

4, winding process considerations

(1) Avoid the enameled wire scratched in the winding process. Because the surface of the enameled wire is an insulating film which is easy to be scratched by the corners of the metal object. Therefore, it is necessary to pay attention to the parts where the mechanical equipment is in contact with the enameled wire during the winding process and minimize the enameled wire on the external force to avoid damage to the paint film.

(2) Winding tension. In the winding process, the tension applied to the enameled wire should be as small as possible to minimize the performance of enameled wire changes.

5, remove the insulation film

(1) combustion method: such as alcohol lamp burning method.

(2) mechanical stripping method: such as a dedicated patent leather stripper.

(3) chemical reagent treatment: such as paint remover.