How to test enameled wire

Regular Enameled Wires Test Items

1. Appearance

2. Dimensions

3. Electrical resistance

4. Brine pinhole

5. Adherence and flexibility

6. Special Enameled Wires Test Items

7. Heat shock

8. Continuity of covering

9. Unidirectional scrape

10. Elongation

11. Resilience

Enameled Wires Test Items——Appearance

1.The labels on spools meet the shipping requirements

2.Spool without breakage, edge without scratching and burrs

3.Enameled wire with uniform color and smooth surface

Enameled Wires Test Items——Dimensions

The measurement of the dimensions shall be measured with an instrument with an accuracy of 1/1000 mm. Take 100cm from each spool as sample to measure the diameter of the sample as a test point.

Ø Insulation thickness

Ø Calculation method : OD - Conductor Size = Film Thickness

Ø Ø Conductor Size

Enameled Wires Test Items——Electrical resistance

Take 1 ± 0.05m length

Under Ambient temperature 20 C℃

Enameled Wires Test Items——Brine pinhole

n 0.2% salt water

n Appropriate amount of 3% phenolphthalein alcohol solution

n connect solution with 12VDC anode, copper with cathode

n Count the number of purple bubbles 1 minute later

n 5 hole / 6m

n Principle:

2Cu + H2O = 2CuO + 2H2↑

Enameled Wires Test Items——Elongation

n Enameled wire should have a certain degree of extension to ensure that the quality of winding

n Different wire sizes have different elongation requirements

n Elongation calculation: δ = (L1 - L0) / L0

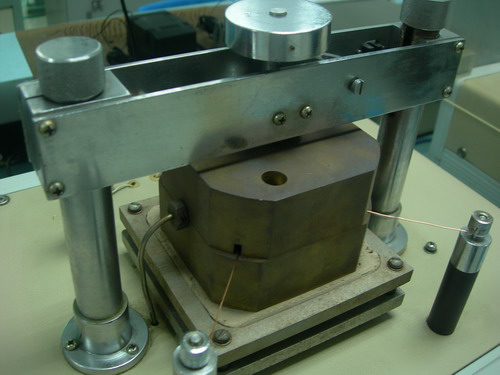

Enameled Wires Test Items——Resilience

n Enameled wire should have a certain flexibility

n Different diameter hanging different weight, in different diameter reel winding 5.5 laps

n Remove the weight, copper rebound, leaning on the lotus sensor

n Instrument rotation, when the coil release stress, the copper wire again after the lotus, the instrument stops rotating, showing the rebound angle reading

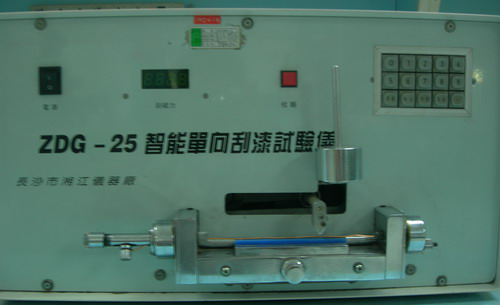

Enameled Wires Test Items——Unidirectional scrape

Make the enameled film coating adhesion quantized

Method:

Select the corresponding weight according to the diameter

Enter the weight of the weight

Start the instrument, direct reading

Enameled Wires Test Items——Heat shock

n High temperature conditions: 220 ℃

n Force conditions: 0.25 ~ 70N adjustable

n Time: 30mins